Torque Converters (CVT’s)

Comet has been manufacturing torque converters for recreational vehicles for over 60 years.Our torque converters are designed and built to withstand the extreme rigors of rough applications. Whenever there is a need, want and use for a torque sensitive drive system device that is infinitely variable from engagement to the highest speeds attainable (within the pitch diameter range), our experience and quality craftsmanship will provide you with an excellent, long-lasting product for your application.

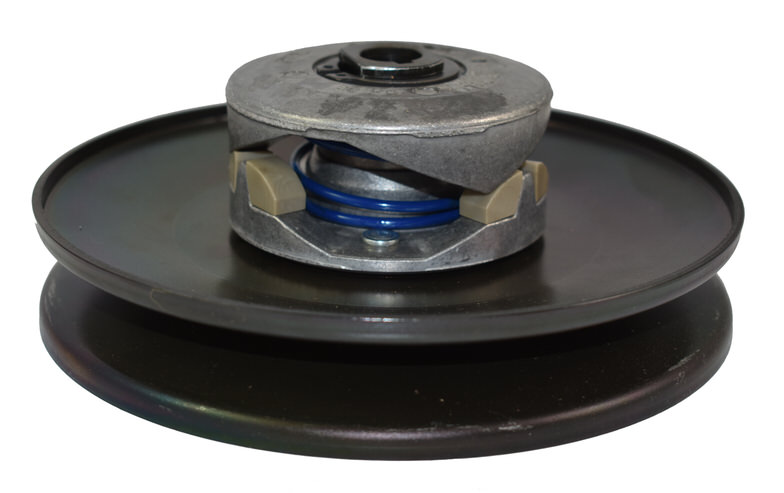

How does a Comet torque converter work? The drive clutch is activated by the centrifugal force from the engine crankshaft. The moveable sheave of the clutch is forced in as the RM of the engine is increased. This contacts the drive belt. The drive belt will then be forced to a larger diameter within the clutch sheaves, thus pulling it to a smaller diameter within the driving unit sheaves. The moveable sheave of the driven unit is forced out, allowing the belt to seek its smaller, high speed ration diameter. As this happens, the speed from the engine transferred to the final drive is increased.

20 Series

The Comet 20 series clutch uses a ¾” top width belt. The belt design adds substantially to the driving ability of the system especially in cases where added torque capacity is required without danger of slipping the belt.

30 Series

The model 30 uses a ¾” top width belt. The belt mass in the 30 series is desirable in applications requiring extra rugged driving ability, such as dune buggies, go-karts, mini-bikes, ATV’s, grounds maintenance equipment, materials handling devices and industrial equipment.

TAV2 Series

The model 30 uses a ¾” top width belt. The belt mass in the 30 series is desirable in applications requiring extra rugged driving ability, such as dune buggies, go-karts, mini-bikes, ATV’s, grounds maintenance equipment, materials handling devices and industrial equipment.

40 Series

The rugged 40 series torque converter is composed of heavy walled stamped steel to withstand the extreme rigors of rough applications.

44 Magnum Series

The Magnum 44 continuously variable transmission torque converter system for up to 18 HP applications is a rugged piece of machinery. The drive clutch is designed to withstand the extreme rigors of rough applications. The driven unit is of the same quality construction as drive clutch.

94C Duster Series

This is the one to use for all V-twins and high torque applications. With a beefy 1 – 3/16” belt, the 94C has the rugged reliability needed when you want to spend your time riding, not making repairs.

102C Series

Designed for snowmobiles and other applications that require a full range of exceptional ability from engagement through the highest speeds available from the power source, the 102 C clutch is one of the best for snowmobiles and other machines using belt driven torque converters.

103 HPQ Series

The 103 HPQ performance clutch for Polaris and Kawasaki ATV’s extensive testing has shown that the 103 HPQ provides up to a 25% enhancement due to a larger diameter pulley and a greater sheave angle then the OEM clutch provides.

108 4PRO Series

We call the 108 4-Pro the Super Clutch as it utilizes four clutch weights rather than three, greatly enhancing tuneability. Arms can be used in sets of two, allowing you to zero in on the amount of weight desired, and a captivated tower allows the shouldered cover bolts to virtually eliminate tower spreading.

108 EXP Series

Designed for snowmobiles and other applications that require a full range of exceptional ability from engagement through the highest speeds available from power source, the 108 EXP clutch is one of the best for snowmobiles and other machines using belt driven torque converters.

500 Series

The model 500 drive and driven variable pulleys are installed in a power train drive system to better match output requirements with an engine output.

780 Series

The highly tunable 780 torque converter drive clutch can be used with your selection of several different driven diameters and spring configurations to obtain the ideal driver to driven ratios for each specific application. Torque sensitive drives are particularly suited to those applications where immediate response to torque demand is required for down shifting and where engine speed is ideally maintained at its peak rpm

1190 Series

The 1190 is for heavy duty applications, the work horse of torque converter systems, for both gas and diesel engines. The super duty drive and driven units are manufactured from heavy gauge stamped steel with optional hard anodized aluminum pulley faces to withstand extreme conditions and abrasive environments.